Innovative New Products for Cannabis Extraction and Particle Analysis from FRITSCH

Extractions best bud has brought some new friends to the party

Fritsch is well-known for their high-performance sample preparation and particle sizing solutions for industry and research laboratories. Backed by a 100-year legacy of innovation, Fritsch precision milling systems are widely used in applications ranging from agricultural analysis to food processing, testing, and more.

The company has made significant impacts on the cannabis industry, with their sample preparation and quality control solutions for cannabis and hemp plant processing. By enabling optimized size, distribution, and consistency of starting materials, Fritsch’s PULVERISETTE 19 Precision Cutting Mill system has set the bar for improved yield and quality in a range of extraction applications.

The company is now set to impact the industry again with the release of two new exciting products – the PULVERISETTE 11 Knife Mill and the ANALYSETTE 22 NeXT Particle Sizing Analyzer platform. We caught up with Melissa Fauth, President and CEO, and Jeff Scott, Business Development Manager, to gain a better perspective of the features and capabilities of these new instruments.

The New PULVERISETTE 11 Knife Mill

Damon Anderson (LabX):

The PULVERISETTE 11 Knife Mill is designed for fast, gentle comminution and homogenization of cannabis samples for analysis and testing. Can you tell us a little more about the basic features of the device?

Melissa Fauth (MF):

The PULVERISETTE 11 provides homogenous sample preparation of cannabis and other materials, rapidly and efficiently.

Device flexibility allows users to address multiple variables in the lab. The mill is compatible with either reusable or single-use -- plastic, glass, or stainless grinding vessels. Sample volumes can range from < 40 mL to 1400 mL. Cryogenic operations can be performed using either LN2 or Dry Ice.

The device is also easy to clean. Quick-disconnect parts permit full disassembly, and all components are dishwasher and autoclave safe. The milling chamber inlay is removable for quick cleaning between runs.

LabX:

Can you describe the range of applications for which the PULVERISETTE 11 is designed?

MF:

The PULVERISETTE 11 is effective for flower, leaf, stem, and stalk materials of cannabis and hemp plants. It is also capable of processing crystalline isolates, distillates, and a wide range of edibles, from gummy candies to chocolates, baked goods, and more -- basically any cannabis material or infused product.

Beyond this, the system is built to handle fast preparation, homogenization, and size reduction of a broad range of material types across industry, research and development, and quality testing laboratory settings.

LabX:

Can you elaborate of the key advancements which make the PULVERISETTE 11 the ideal knife mill for these applications?

MF:

The design includes programmable and manual operation settings, which allow users to customize performance based on the requirements of each sample type. Users can create and store up to 20 SOPs (standard operating procedures) for optimal consistency and repeatability. Speed can be adjusted up to 14,000 rpm, in continuous or interval operation, and achieve up to 56,000 cutting processes per minute. The system also has reverse and high power burst functions.

Use of premiere blade technology provides secure blade fastening to the chamber base. Multiple geometries provide ideal settings to match the specific physical properties of each sample. The safety chamber with interlock protects users and the environment, while the motor block and housing engineering protect samples from heat exchange, preventing physical and chemical loss.

LabX:

How does the PULVERISETTE 11 complement the FRITSCH portfolio of cutting mills and sample preparation solutions?

MF:

The PULVERISETTE 11 fills a role with versatility for users that require processing of small to mid-range volumes in the laboratory. It expands capabilities beyond the targeted physics behind our historic milling instrumentation line. This Knife Mill allows labs to affordably handle ever increasing diversity in difficult materials, that require representative sample for critical (and accurate) analytical testing.

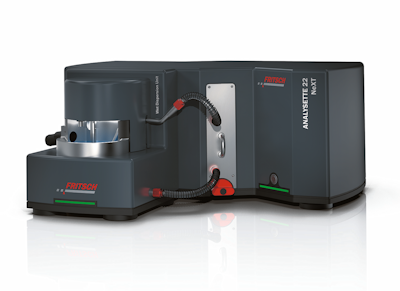

The New ANALYSETTE 22 NeXT Particle Analyzer

The ANALYSETTE 22 NeXT Micro and Nano devices adopt a no non-sense mantra “Particle size distribution? Keep it simple!”. Although operation may be straight forward, the engineering behind these devices is exquisite. The compact laser particle size analyzer comes in two versions to cover an extra wide measuring range. The ANALYSETTE 22 NeXT Micro is suited for all typical measurement tasks from 0.5 to 1500 µm. The ANALYSETTE 22 NeXT Nano is capable of an extra-wide measurement range from 0.01 to 3800 µm, for maximum precision and sensitivity on even the smallest particles.

LabX:

What are the main applications for these devices?

Jeff Scott (JS):

The ANALYSETTE 22 NeXT instruments are ideal for ensuring that hemp and cannabis materials are the proper size in order to maximize extraction process yield.

In production and quality control, these devices are used to ascertain that the final fineness of the milling process has been achieved. This is essential in quality control during the production of CBD isolate materials, for instance, to ensure the correct particle size is obtained and maximum product benefits to the end user are met.

The instruments are well-suited for research and development as well, for instance, in determining particle size distribution during the formulation of new powders and emulsions.

LabX:

On the technical side, can you describe the key performance features of the NeXT Micro and Nano instruments?

JS:

These devices are static light scattering (laser diffraction) particle size analyzers with a new compact, space-saving design. They utilize a single laser (green, 532 nm, approx. 1 mW) to achieve a wide measurement range, with minimal time requirements. Shorter alignment, background, and measurement times equate to end-to-end analysis in as little as 10 s.

The new sample cell design allows for wider scattering angles for measurement of particles in the nanometer size. The wet dispersion unit is totally redesigned over previous devices. The measurement circuit is compact, with minimal dead space, and the simpler design contains fewer moving parts and no complex valves of moveable seals. In addition, pH and temperature of the circulation water can be measured and stored as useful data parameters of suspension stability.

The wet dispersion unit uses a continuously variable return pipe which allows sample material flowing back from the measuring cell to be fed into the dispersion bath. This can be adjusted to create a swirling effect that keeps the suspension in constant motion, increasing accuracy and reproducibility of measurements.

The devices are also easier to clean and to replace lenses without tools. The “hood” of the wet dispersion unit is easily removed and allows for easy access for cleaning of the dispersion bath.

LabX:

What advantages do the NeXT Micro and Nano provide over traditional particle sizing technologies?

JS:

These instruments provide reproducible, repeatable results in less time. The instruments are operated by the use of SOPs (Standard Operating Procedures). This allows for repeatability in analysis results regardless of the end user. SOPs are part of ensuring that GLP’s (Good Laboratory Practices) are maintained and followed in the laboratory.

LabX:

Can you provide a few words regarding the value proposition of these devices and FRITSCH portfolio of products?

JS:

Experience. Whether its measuring your particles or preparing your samples for analysis, ensuring you have a representative sample or just simply milling materials to a specific size, FRITSCH has a total turnkey solution to suit your needs.

View more information on the PULVERISETTE 11 Knife Mill

View more information on the ANALYSETTE 22 NeXT Micro and Nano Particle Size Analyzers