The Success of Beadbeater Bead Mill Technology in Life Science Research

Adaptability and efficiency make beadbeating the ideal cell disruption technique in modern research labs

Cell Disruption – The Concept and the Need

Tissue homogenization has a rich history across many disciplines, from pathology to developmental biology and most areas in between. Cutting mills, blenders, and similar methods were the traditional methods preferred for production of homogenates of plant and animal tissues. As the molecular era evolved, and investigators began to drill down to the cellular level, the need for precise and effective cell disruption techniques became apparent.

Today there are many techniques for mechanical disruption of cells and tissues, each with their preferred applications, strengths, and limitations. Bead mill homogenization has emerged as the premier method of choice for life science researchers, owing to superior results matching the various needs of modern molecular research laboratories.

Traditional Mechanical Disruption

Cutting-blade type blenders and rotor-stator homogenizers harness the force of mechanical sheer stress to tear apart membranes. This high-sheer action can result in complete cell dissolution depending on the sample type and force used.

Tissues Grinders disperse and disrupt tissue samples by using repeated pressurized squeezing between two hard surfaces.

Cryogrinders provide access to soft tissues with high water content, which are frozen at dry ice or liquid nitrogen temperatures (< -80 degrees Celsius) and then fractured into powdered material.

Ultrasonication devices generate intense sonic pressure waves in liquid samples, and the resulting cavitation produces enough energy to break cell membranes and even break covalent bonds.

All of these mechanical disruption techniques come with obvious advantages. There are certain potential drawbacks as well, however, such as excess heat generation during ultrasonication or foaming at the air interface during wet mixing. Moreover, these methods may be of limited utility in applications where membranes and cell organelles must remain intact, where delicate cells are processed, and/or when protein/DNA/RNA integrity is paramount. Scalability is also an issue with some disruption methods. They cannot process milligram quantities of tissue or, conversely, cannot be applied to production-scale cell lysis.

Modern Bead Mill Homogenization

The advent of the bead beating technique, pioneered by BioSpec Products in the late 1970’s, combined aspects of mechanical stress techniques with the use of easily adaptable parameters to accommodate different membrane and cell disruption applications. Bead milling involves addition of large amounts of minute glass, ceramic, or steel beads to sample tubes or vessels. Vigorous agitation by shaking or stirring gives rise to cell disruption as beads collide with cells. As opposed to the ultrasonic or high-pressure methods described above, wet bead milling entails low shearing force. By altering the size, density, and shape of beads, and the parameters of agitation, bead milling affords a multitude of applications in the laboratory.

Key Features of Bead Mill Homogenizers and their Applications

The bead beating method is now the method of choice for disrupting microorganisms, spores, fungi, and tough membrane cells such as cyanobacteria and microalgae. More recently it has been successfully applied to a large variety of animal and plant tissues and for soil and materials analysis. The option for single-use processing, a totally sealed cell lysis system, and the capability to process very small quantities of sample make it ideally suited for PCR and other chemically sensitive molecular methods.

Bead size and composition

In bead beating, the bead diameter is important. Optimal size for bacteria and spores is 0.1 mm, while 0.5 mm is ideal for yeast, microalgae, and other eukaryotic cells. Animal and plant tissues necessitate 1.0 to 2.5 mm bead sizes.

The bead composition is also important, affecting both the speed of bead agitation and the force at which cells are impacted. This translates to the type of cells that can be disrupted -- glass beads for standard cells and soft tissues, ceramic beads for tougher cells, and steel beads for fibrous or dense tissue samples. The use of sharp-edged non-bead particles made of garnet or silica carbide perform well in disrupting especially difficult tissues. The use of more durable polypropylene or steel microvials can prevent cracking or breaking of vessels during high-energy agitation using steel beads.

An extensive portfolio of bead types and sizes, as well as particle and vessel types, are available from BioSpec Products.

Agitation method

The mode of agitation also affects the rate and efficiency of disruption. Shaking-type bead mills hold 0.6 to 50 mL screw top vials in either vertical or near horizontal position. The pattern of shaking can either be linear or a figure-8 pattern roughly aligned along the vial axis. Vial orientation and shaking duration impact the efficiency of tissue and/or cell disruption as well.

BioSpec Products offers several models of high-energy, laboratory-scale shaking bead mills. The MiniBeadbeater-Plus holds one standard 2 mL screw-cap microvial at a time, while the MiniBeadbeater-16 and MiniBeadbeater-24 (shown) models can process up to 16 and 24 two mL microvials in tandem, respectively. The MiniBeadbeater-96 processes samples loaded into 1 mL or 2 mL deep-well microplates, as well as samples in standard 2, 7 and 50 mL screw-cap vials.

Innovation in shaking bead mill technology has led to impressive advancements in performance. The latest addition to the BioSpec lineup, the SoniBeast (shown), uses proprietary ultra-high vortex motion driven by a 21,000 rpm (350 Hz) motor. The SoniBeast can process twelve 0.6 mL microtubes or three 2 mL microvials. Importantly, it can disrupt cells in seconds, not minutes, and is the fastest bead mill on the market.

Also available from BioSpec is the hand-held, cordless Sonibeast-Jr, a smaller capacity version of the Sonibeast. Designed for samples taken in the field or other locations distant from a diagnostic laboratory, it is powered by a rechargeable lithium battery and homogenizes plant and animal tissues in either two 2 ml microvials or one 7 mL vial.

Sample size and throughput

Scaling up to larger sample sizes requires mills capable of handling the consistency of disruption as well as the dissipation of heat and other factors.

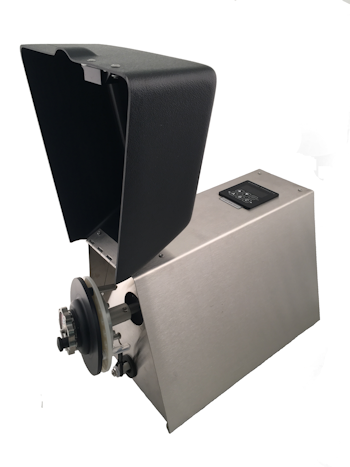

For larger applications, BioSpec offers the rotor-type bead mill, the BeadBeater (shown). This device can process up to 80 g (wet weight) of microbial cells suspended in 250 mL of disruption media, while smaller attachments can process 15- or 50-mL batches. Importantly, this compact laboratory-sized device requires only 3-5 minutes per cycle.

The BeadBeater is the starting point for recombinant protein recovery. Protocols developed with the BeadBeater are directly transferable to production-sized bead mills.

Summary

BeadBeater mills have solidified their place as the preferred method for cell disruption in modern life science research labs. The adaptability and efficiency of the technique make it ideally suited for many different cell types, sample numbers, and sample sizes, among other parameters.

Blade-type blenders, rotor-stator homogenizers, grinders, and (cryo) pulverisers all serve important roles in research and industry as well. BioSpec Products offers a large variety of devices for a range of tissue and cell disruption applications. Take a look at the available products for more information and links to additional resources.

This editorial was written by LabX and published in collaboration with BioSpec Products.