The Beadbeater and the Evolution of Mechanical Cell Disruption Technologies

The onset of the age of molecular biology created a growing need to capture fluids, organelles, and molecules, such as DNA and RNA, from a broadening range of biological samples.

Cell disruption technologies evolved to meet these demands. Today there exists a wide range of mechanical cell disruption techniques capable of processing everything from tough tissues such as seeds and connective tissues to microorganisms and spores.

Mechanical cell disruption

Cell disruption by the use of mechanical force can involve either high-pressure shear, grinding with beads, cutting blades, or ultrasonication. The shearing, crushing, or cavitation actions of these techniques result in lysis of cell membranes and release of cell contents suitable for downstream applications.

Bead mill cell disruptors

Bead Mill cell disruptors (commonly referred to as Beadbeaters) have displaced many older, less efficient methods and are now commonly used in the lab for cell lysis applications. The method involves the use of small, inert beads added to sealed sample tubes or vials. Upon high energy shaking or stirring, the crushing action of the beads on cells within the vessel results in highly efficient cell disruption. This action differs from high-pressure or sonication techniques which employ high shear forces.

Advantages of bead mills

Advantages of Beadbeating include the ability to handle relatively delicate cells such as microorganisms and recover cell membranes and intracellular organelles by adjusting the size of the beads and/or the proportion of beads to cell sample size. Beadbeating is also the method of choice for microbial spores, cyno- and mycobacteria, microalgae, and small samples of plant and animal tissue, for which alternative methods may be suboptimal.

Advantages also include the ability to scale-up or down by changing the number or size of vessels used per batch, as well as options to control sample preparation rates and sample temperatures. Importantly, the potential for cross contamination is completely eliminated by the use of sealed disposable tubes and beads. Limitations imposed by tough tissues can usually be handled by the use of more dense bead materials such as zirconia or steel, or other bead types consisting of sharp-edged particles. The Beadbeating method can be easily scaled up to pilot plant and full production levels, further extending the reach of this technology.

Beadbeater history

Beadbeating technology in the laboratory was pioneered by Tim Hopkins and originally commercialized by BioSpec Products in the late 1970’s as a complement to a growing portfolio of cell disruptor solutions. With the advent of many other products and accessories over time, BioSpec and others have helped galvanize beadbeaters as the preferred device for a large array of lab applications.

Over time, continued innovation has focused on the needs of labs and the desire to access a growing number of tissue and cell types and components. Popular examples include: nucleic acid extractions for sensitive sequencing methods, bacteria and fungal cells from novel and emerging sources, and detailed imaging and structural studies on intact cell organelles.

Scale and speed

The original device, the BioSpec Mini-Beadbeater, has evolved into several devices optimized for a range of sample sizes and vial capacities. Current BioSpec models can be subdivided into four categories based on the motion of agitation, the speed of disruption, and the sample volume or scale.

- The BioSpec SoniBeast uses patent-pending milling technology which delivers much faster disruption, up to 10x faster than the typical 1-3 min rate of convention bead mills.

- The Mini-Beadbeater-Plus processes 1 to 400 mg of tissue in one 2 ml screw-cap microvial, while the Mini-Beadbeater-16 and Mini-Beadbeater-24 units have multi-vial capacities and can process samples in both 2 and 7 ml microvials.

- The high-throughput Mini-Beadbeater-96 processes 1 to 2 deep well microplates, or racks holding fortyfive 2 ml microvials, four to twelve 7 ml vials or two 50 ml tubes.

- The large capacity Beadbeater, which uses a Teflon rotor to stir the beads at high speed, can process up to 10-80 g wet weight bacterial or monocellular plant or animal samples.

Bead types and applications

The capabilities of the Beadbeater method have grown significantly owing to innovations in bead materials, bead diameters, and applicable methods. BioSpec has put significant effort into understanding optimal bead size and behavior for given cell disruption applications.

- Glass or dense Zirconia beads are ideal for general cell or tough tissue lysis, respectively.

- Chrome steel or stainless-steel beads are used primarily for grinding leaves and seeds.

- Silicon carbide or garnet shaped particles have sharp cutting edges ideal for lysing tough plant and animal tissue.

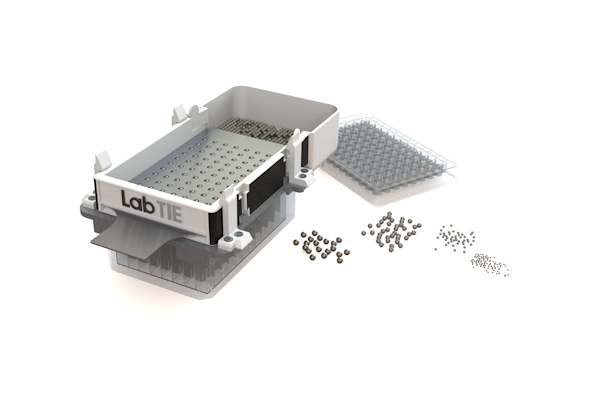

Vials, microplates, and bead loaders

A large variety of vials, microplates, loaders, and other accessories accommodate the expanded portfolio of bead types and applications.

- BioSpec offers polypropylene tubes and microvials of various volumes, as well as racks to accommodate multiple sample vessels.

- Special reinforced XXTuff microvials and stainless steel microvials are available to withstand vial fracture when grinding using steel beads.

- Deep well microplates with sealing mats optimized for beadbeating permit parallel processing of thousands of samples for high-throughput applications.

Portfolio of cell disruption products

BioSpec’s focus goes beyond the beadbeating method of cell disruption solutions. The company provides an ever-broadening portfolio of products and applications designed to address cell disruption and tissue dispersion.

- BioSpec offers rotor-stator homogenizers, blade cutters, and tissue grinders, optimized for performance and durability.

- Tissue pulverisers are also available, including the Biopulverizer, BioSqueezer, Cryo-Cup Grinder, and MicroCryoCrusher devices. These devices are used on tissue hard-frozen in liquid nitrogen.

- A range of tissue dispersers, mixers, and stirrers are designed for processing small volumes of tissue. The dispersers are often used for the preparation of viable single cells.

- A line of tissue extraction tools to process larger sample sizes, from seeds and grains to fruits and vegetables, offers a step to scale up to production volumes.

BioSpec Products is best epitomized by their homepage message… “WHO WE ARE... BioSpec Products has provided innovative laboratory equipment for 40 years. Most of our products are of our design. And, many are industry "firsts." For example, it was our Mini-BeadBeater™ line that founded the popular cell and tissue disruption method now commonly referred to as "beadbeating". We concentrate on developing quality products priced at affordable prices. Customer care is one of our specialties. Please contact us for sound, informed advice.”

View BioSpec listings on LabX.com

This article was written by LabX and published in collaboration with BioSpec Products.