5 Ways In-House Cannabis Testing Can Help Your Cannabis Business

When it comes to cannabis cultivation, is in-house testing necessary? What are the benefits of being able to test your cannabis plants on-site?

When cultivating cannabis, knowledge is power. The more you know about the plants you’re growing, the greater your yields will become. Plus, by keeping a close eye on your cannabis throughout the cultivation process, you can catch pests and other problems early, reducing potential damage.

Growing cannabis isn’t like cultivating any other plant. A competitive market demands reliably high quality, but at the same time, onerous regulations are waiting to swallow cannabis producers who make seemingly forgivable rookie mistakes.

Whether it’s getting to know your plants better or catching potential issues before regulators do, investing in in-house cannabis testing equipment is an excellent way to improve yields and bud quality while saving on operational costs long-term. Let’s take a look at five specific ways in-house testing can improve your cannabis business:

#1 Getting intimate with your plants

Recent research indicates you might want to talk to your cannabis plants to stimulate their growth. Regardless of how much you talk to your plants, though, they won’t talk back. That means they won’t tell you when they aren’t getting the nutrients they need or if they’re being plagued with pests.

The only way to know your cannabis plants on an intimate level is with in-house testing. There are countless things your plants are trying to tell you all the time, but our human senses aren’t capable of making them out. To understand what plants are trying to tell us, we need to use contemporary testing.

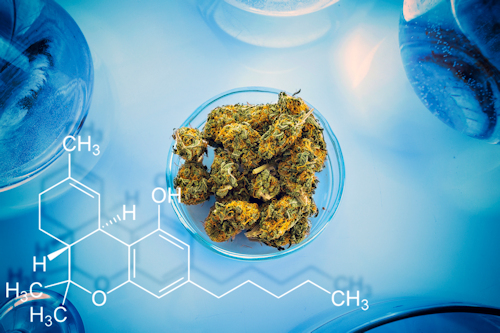

Using advanced molecular measurement technologies like spectroscopy combined with cutting-edge data analytics, it’s possible to render detailed data on a cannabis sample within less than five minutes. Portable, professional-grade spectroscopy devices like the GemmaCert Pro provide nearly instant information on cannabis moisture content, potential mold growth, cannabinoid levels, and terpene concentrations.

#2 Optimizing your yield

Every cannabis grower dreams of thick, juicy colas that are practically dripping with cannabinoid-rich trichomes. In practice, though, optimizing the yield of your cannabis plants can sometimes be frustrating.

Genetics provide hard limits on cannabis yield, but it’s possible to bring your plants to the highest potency their strains allow by catching potential issues early on. Nutrient deficiencies, improper lighting, and pests can all reduce a cannabis plant’s yield, and in-house testing is the best way to note these problems before they start stunting the growth of your plants.

One of the biggest factors that affects cannabis yield is harvest timing. By tracking your cannabis throughout the cultivation process, you can ensure you won’t harvest your plants too soon or too late.

#3 Tracking your performance

Numbers don’t lie. In the end, you might have to admit you’ve been avoiding performing proper analytics because you’re afraid you’re actually doing worse than last year.

If you face that fear of failure, though, tracking your progress with analytics is one of the best ways to ensure your cannabis cultivation practices are yielding good results. Test your products at the end of every day, and start keeping a database of your successes and failures.

You would have never known to celebrate the successes you uncovered without proper analytical performance tracking. Even the failures you may feel ashamed to log in your database are lessons you wouldn’t have learned if you hadn’t decided to start tracking your day-to-day cannabis production performance.

#4 Staying ahead of regulations

Mislabeled and contaminated products abound within the cannabis and CBD industries, but there are still no federal requirements for in-house testing of hemp or cannabis. In states that have legalized cannabis, products must be tested by third-party facilities prior to sale to prevent contaminated cannabis from entering the market. Almost every state with a medical or recreational cannabis program, however, has experienced severe difficulty with testing standardization and improper practices in cannabis testing labs.

Instead of waiting until the last minute to discover your products are contaminated—and therefore out of compliance with regulations—catch issues in the bud with in-house testing. In the future, the FDA may implement in-house testing requirements for cannabis and hemp producers to prevent product contamination and dishonesty among cannabis testing labs.

Regardless of what the government might regulate, it’s only right to prevent your customers from using contaminated, unsafe products. It may still take years, but the cannabis and hemp industries will one day be regulated just like any others. When that day comes, you’ll want to have already been performing adequate testing for years instead of forcing yourself to catch up all at once.

#5 Saving on testing costs

Let’s lay out a story that might sound familiar to many cannabis producers. You need to test each batch of products before it’s sold, and you happen to have an old friend who runs a cannabis testing lab. You send finished products over to your friend for testing, and more often than not, there are issues that need to be addressed.

In the end, you might need to send your testing lab the same product two or three times before you’ve worked out all the kinks. Your friend is happy to offer bulk discounts on testing, but you end up wondering if the whole back-and-forth process of sending products in for testing multiple times is self-defeating.

Why not make sure your products are ready for testing before they head out your door? In many states, third-party testing is required for cannabis, but no one ever said you needed to pay to have the same product tested multiple times.

In-house cannabis testing equipment can seem expensive at first, but when you factor in the number or times you’ll shell out fees to a third-party testing agency for products that aren’t even ready for sale, the price of having the power to test your cannabis at your own facility starts to seem considerably lower in comparison.

What is the best way to test cannabis in-house?

Recent technological advancements have made it possible to perform lab-grade analytics on cannabis samples from the comfort of your own facility. Previously, it was necessary to purchase the same type of bulky equipment testing labs use to get accurate results. Portable cannabis analytics solutions like the GemmaCert Pro, however, are empowering average cannabis growers to get the types of results provided by professional lab equipment using a device that fits into a kit the size of a briefcase.

Over the next few years, it’s likely that many states will organically start moving away from the clearly failed third-party testing requirement for cannabis and start embracing the benefits of in-house testing instead. The GemmaCert Pro already represents an excellent tool for tracking your performance, optimizing yields, and saving on testing, but reliable in-house cannabis testing devices may become absolutely necessary in years to come.

Providing detailed data on sample potency and purity in mere minutes, the GemmaCert Pro includes the same high-end spectroscopy technology used in modern labs—just miniaturized. Empowering growers to overcome today’s challenges and face the future’s requirements, in-house testing has the potential to take cannabis cultivation to a whole new level of potency, safety, and reliability.